Why SMT Companies Choose Holang Modular Nitrogen Generator

發(fā)布時(shí)間:2023-03-10 瀏覽次數(shù):1039

In the previous article, we explained the role of nitrogen in the production of the SMT industry, and its role in soldering has been verified in the SMT industry. As for obtaining nitrogen, with the progress of production, we have many ways, and we have detailed various methods of obtaining and cost analysis in the article "How to Obtain Nitrogen Source Correctly in the SMT Industry". In the production of the SMT industry, many enterprises are willing to choose Holang modular nitrogen generator. In addition, Holang modular nitrogen generators can be found everywhere in industries such as food and medicine, 3D printing, laser cutting, laboratories, and new materials. Why choose Holang? Why choose a modular nitrogen generator?

HOLANG TECH

Holang Tech (Suzhou) Co., Ltd. (hereinafter referred to as Holang) is an innovative technology enterprise dedicated to professional innovation and services in the forefront of industrial gas technology. We focus on scientific and technological research and development, provide customers with more comprehensive, convenient, and caring services, constantly pursue innovative products and improve service models, extensively cooperate with domestic and foreign scientific research institutes in product development, design, and scientific research, and create higher value for customers.

Corporate culture

The HPL series modular nitrogen generator, as the latest generation of products independently developed by Holang, works based on the Pressure Swing Adsorption (PSA) principle, which uses clean air as raw material and high-quality carbon molecular sieves as adsorbents to adsorb oxygen, carbon dioxide, and water at a certain pressure, while nitrogen cannot be adsorbed and flows out from the top of the cylinder after passing through the sieve. According to different on-site gas usage needs of customers, the HPL series can provide high-quality nitrogen with different flow rates and purities. At the same time, the HPL series also absorbs the advantages of membrane separation products, its excellent nitrogen quality and plug-and-play convenience are more easily accepted by customers.

The Pressure Swing Adsorption (PSA) gas separation technology is an important branch of non-cryogenic gas separation technology, and it has an irreplaceable position in on-site gas supply in today's world. The HPL series modular nitrogen generator is mainly composed of two adsorption cylinders A and B assembled with carbon molecular sieves and a control system. When compressed air (with a pressure generally around 0.7 MPa) passes through group A from bottom to top, oxygen, carbon dioxide, and water are adsorbed by the carbon molecular sieve, while nitrogen cannot be adsorbed and flows out from the top of the cylinder after passing through the sieve. When the molecular sieve in group A is saturated, it switches to group B for the above-mentioned adsorption process and regenerates the molecular sieve in group A at the same time. Regeneration refers to the process of releasing the oxygen, carbon dioxide, and water absorbed by the molecular sieve from the molecular sieve by discharging the gas in the adsorption cylinder to the atmosphere, which makes the pressure rapidly drop to atmospheric pressure.

Main features of product

Compared with traditional Pressure Swing Adsorption nitrogen generators (AB tanks), the HPL series looks more beautiful in appearance, occupies a smaller area, and has low noise during machine operation due to the effect of customized mufflers and sound insulation cotton in the box, and does not require a separate machine room, which is more suitable for on-site use. In terms of structure, the HPL series does not include pressure vessels, which are safe, convenient, and fast to use, avoiding inspection and annual review. The HPL series container uses aerospace-grade aluminum alloy, which has better corrosion resistance, while the materials used in AB tank equipment are mostly made of carbon steel, which will corrode to varying degrees as time goes by. In addition, the HPMN series can be expanded and upgraded. When we need a larger gas flow rate, we can add a container to the rear of the original cylinder. AB tank equipment is a customized equipment. If we want to increase the gas flow rate, we can only replace it with a new equipment, which will increase the cost and delay the actual production use in terms of economic efficiency.

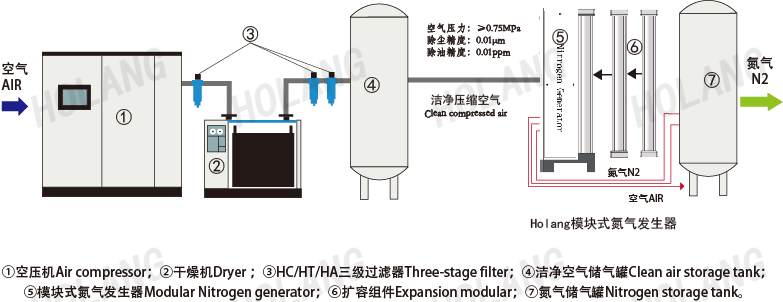

No matter what level of nitrogen you need, Holang can customize a solution that meets your specific industry application needs. The following figure is a typical installation example, which includes a complete nitrogen manufacturing system.

Nitrogen system flow diagram

Nitrogen is a colorless, odorless, and inert gas with low production cost and high efficiency. Therefore, nitrogen can be seen in various industries. With the progress of science and technology and the development of economic construction, the application of nitrogen is increasingly widespread, and it has penetrated into many industrial sectors and daily life fields. At the same time, Holang modular nitrogen generators will also enter various industries to assist in industry production.

Seeing this, I believe that many companies have a certain understanding of modular nitrogen generators. If you need it in production, please contact Holang's 7*24 service hotline 0512-65685667. In addition, Holang's products include not only modular nitrogen generators but also modular oxygen generators, various gas purification and separation equipment, coarse, medium, and high-efficiency filters, high-efficiency air outlets, FFUs&EFUs, etc.